Stainless steel and carbon steel tube heat exchangers have their own advantages in heat transfer efficiency, as shown below:

一、 Stainless steel heat exchanger

Stainless steel heat exchangers can maintain excellent performance in various complex environments due to their good corrosion resistance, high temperature resistance, and strength. The heat transfer effect is mainly affected by the following factors:

1. Thermal conductivity: Although the thermal conductivity of stainless steel is not as good as some pure metals, it is sufficient to meet most heat transfer needs. The thermal conductivity of different types of stainless steel may vary slightly, such as 304 stainless steel and 316 stainless steel, and the heat transfer efficiency may also differ under the same conditions.

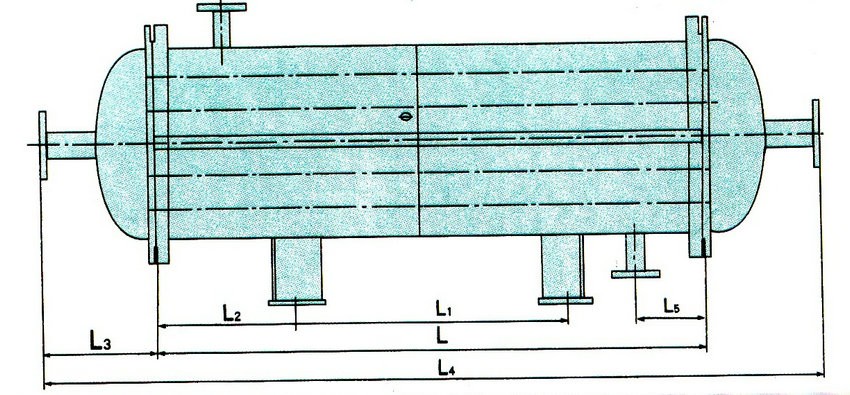

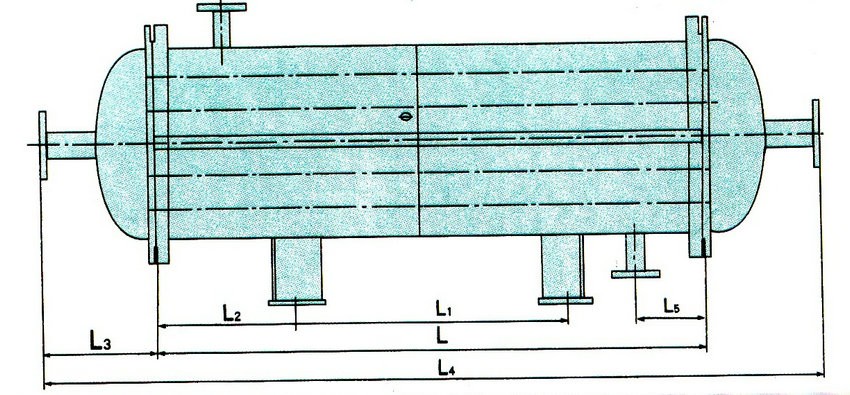

2 Design structure: The heat transfer area of a stainless steel heat exchanger is mainly determined by its internal pipes, fins, and other structures. A larger heat exchange area can provide more heat exchange sites, thereby improving heat exchange efficiency. For example, a heat exchanger with fins can increase the surface area in contact with fluid 3, allowing heat to be transferred over a larger range.

4. Fluid flow velocity: The flow velocity of the heat transfer oil and the heated (or cooled) fluid in the heat exchanger has a significant impact on the heat transfer efficiency. Fast flowing fluids can timely carry away or replenish heat, maintain a large temperature difference, and thus improve heat transfer efficiency.

5. Scaling and blockage: If the internal surface of the heat exchanger is scaled or blocked by impurities, it will reduce the actual heat transfer area, hinder heat transfer, and lower heat transfer efficiency. Therefore, regularly cleaning the interior of the heat exchanger is the key to maintaining its efficient operation.

6 Temperature distribution: Within the heat exchanger, the uniformity of temperature distribution is also important. If there are localized high or low temperature areas, it will affect the overall heat transfer efficiency.

二、 Carbon steel tube heat exchanger

Carbon steel tube heat exchangers are widely used due to their low cost and good processing performance. The heat transfer effect is mainly affected by the following factors:

1 Thermal conductivity: The thermal conductivity of carbon steel pipes is affected by the carbon content. The higher the carbon content, the lower the thermal conductivity, because the heat transfer value of carbon is very low, which will to some extent hinder the transfer of heat. However, the thermal conductivity of carbon steel pipes can be smoothed by controlling their wall thickness to achieve the desired heat transfer effect.

2 Corrosion resistance: Carbon steel pipes have relatively weak corrosion resistance and are easily damaged in highly corrosive environments. Therefore, when used in highly corrosive media, surface treatment such as galvanizing is required for carbon steel pipes to improve their corrosion resistance and service life.

3 Fluid properties: Similar to stainless steel heat exchangers, the heat transfer efficiency of carbon steel tube heat exchangers is also affected by fluid properties. The thermal conductivity, specific heat capacity, viscosity, and other properties of thermal oil, as well as the properties of the fluid being heated or cooled, can all affect the efficiency of heat transfer.

Overall, stainless steel heat exchangers, with their excellent corrosion resistance and high temperature resistance, can maintain efficient heat transfer in various environments; Carbon steel tube heat exchangers are widely used due to their low cost and good processing performance, but require additional surface treatment in highly corrosive media to improve their corrosion resistance. When choosing a heat exchanger, a balance should be made based on the specific usage environment and requirements.

Address:Room 1202, Detaitang Building, No. 118 Huaguang Road, Zhangdian District, Zibo, Shandong

Address:Room 1202, Detaitang Building, No. 118 Huaguang Road, Zhangdian District, Zibo, Shandong WhatsApp:+8613386433135

WhatsApp:+8613386433135 Tel: +8613386433135

Tel: +8613386433135