The impeller agitator is a device used in the coagulation and sedimentation process to mix suspended solids in water with flocculants. Generally, impellers are installed vertically in circular (or square) water tanks. The ratio of pool diameter to impeller diameter is generally 2-6. The water flow in the pool is an axial flow with rapid radiation. The water flows through the pool from top to bottom, with a residence time of 0.75-5 minutes and a stirring time of 30-150 seconds. The advantage of this device is that it can flexibly adjust the mixing speed according to the amount and quality of water being processed.

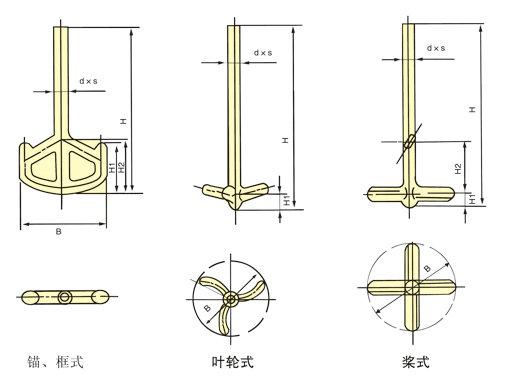

The anchor stirrer has a simple structure and is suitable for stirring fluids with viscosity below 100 Pa · s. When the fluid viscosity is between 10 and 100 Pa · s, a transverse blade can be added in the middle of the anchor propeller, which is a frame stirrer, to increase mixing in the container. The shape of the outer edge of the blade should be consistent with the inner wall of the mixing tank, with only a small gap between them, which can remove viscous reaction products attached to the tank wall or solid matter accumulated at the bottom of the tank, and maintain good heat transfer effect. The peripheral velocity of the blade edge is 0.5-1.5m/s, which can be used to stir Newtonian and quasi plastic fluids with viscosity up to 200Pa · s (see viscous fluid flow). However, when stirring high viscosity liquids, there is a large stagnant zone in the liquid layer.

Special frame anchor mixer:

This type of mixer is a slow speed mixer commonly used in processes such as mixing of medium to high viscosity liquids and heat transfer reactions.

When the anchor frame type (MKS) rotates at low speed, it can obtain a large shear force along the wall, which can prevent settlement and wall adhesion. The bottom shape conforms to the elliptical tank and the bottom bearing in the middle.

2. Anchor Belt (MDS) is a combination of ribbon and frame mixers, combining the functions of ribbon and frame mixers.

3. Box type (FKS) and square grid type (FSS), with simple shapes and easy production, have the same efficiency as box type, and are more suitable for mixing and dissolving with medium viscosity.

4. Plate and frame (BKS) anchor mixer is a mixing impeller with a wide range of viscosity applications. The impeller structure is simple, and the projected area of the impeller on the longitudinal section of the mixing tank accounts for a large proportion of the longitudinal section area of the tank. It has high mixing efficiency and significant shear force, suitable for solid-liquid suspension, liquid-liquid dispersion, as well as gas-liquid mass and heat transfer operations that allow gas to be drawn in from liquid surfaces.

Address:Room 1202, Detaitang Building, No. 118 Huaguang Road, Zhangdian District, Zibo, Shandong

Address:Room 1202, Detaitang Building, No. 118 Huaguang Road, Zhangdian District, Zibo, Shandong WhatsApp:+8613386433135

WhatsApp:+8613386433135 Tel: +8613386433135

Tel: +8613386433135