The enamel glass distillation tank is a composite material product made by lining glass containing high silica on the inner surface of a steel container and firmly adhering it to the metal surface through high-temperature burning. Therefore, it has the dual advantages of glass stability and metal strength, and is an excellent corrosion-resistant equipment widely used in industries such as chemical, petroleum, pesticide, and food.

Thickness of enamel layer: 0.8-2.0mm

High voltage test: 20kV

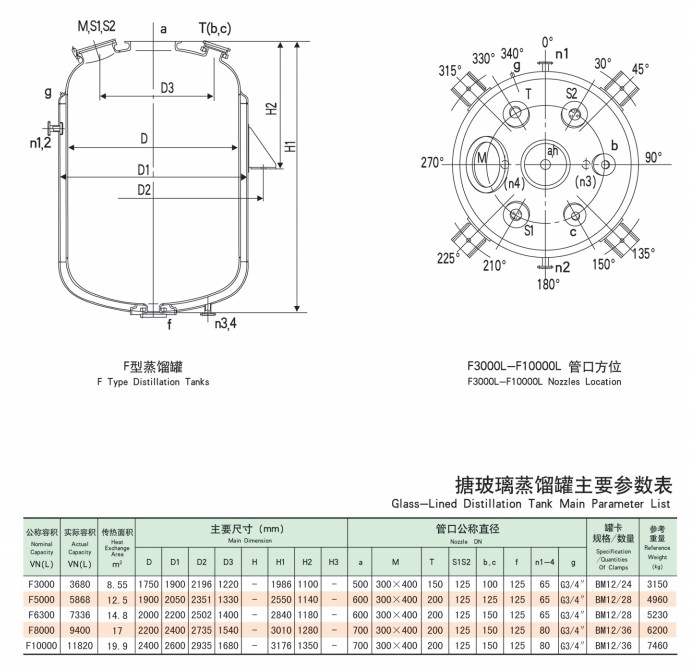

Specification of enamel glass distillation tank: 50-30000L

Distillation is a thermodynamic separation process that utilizes the different boiling points of individual substances in mixed liquids or mixed liquid solids to evaporate low boiling point components and then condense them to separate the entire component. It is a combination of evaporation and condensation unit operations. Compared with other separation methods such as extraction and adsorption, its advantage is that it does not require the use of solvents other than system components, thus ensuring that no new impurities are introduced. Glass lined distillation tanks are widely used in industrial distillation processes due to their corrosion resistance, high temperature resistance, and strong pressure resistance.

Address:Room 1202, Detaitang Building, No. 118 Huaguang Road, Zhangdian District, Zibo, Shandong

Address:Room 1202, Detaitang Building, No. 118 Huaguang Road, Zhangdian District, Zibo, Shandong WhatsApp:+8613386433135

WhatsApp:+8613386433135 Tel: +8613386433135

Tel: +8613386433135